Diecasting in Malaysia: The Engine Behind Precision Manufacturing

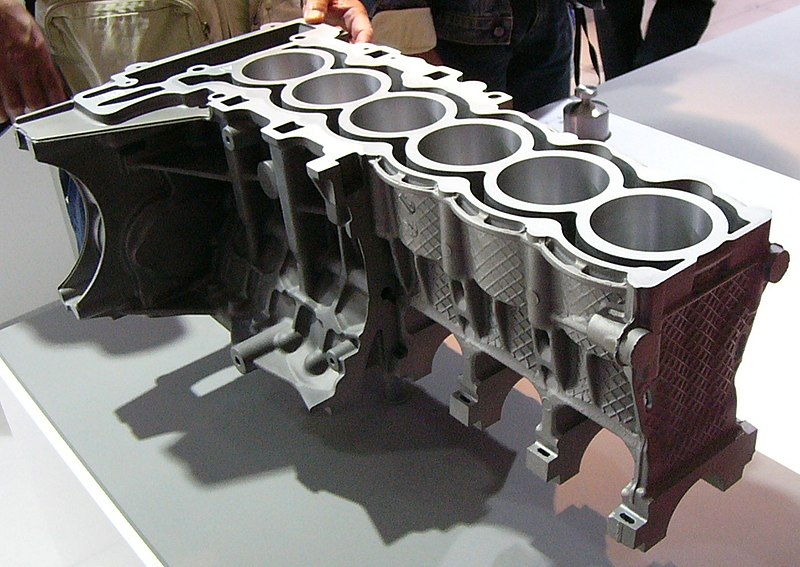

Diecasting has become an important process in the manufacturing landscape of Malaysia, functioning as an important approach for producing accuracy steel elements. With the country's growing industrial field, especially in vehicle, electronics, and consumer goods, diecasting has actually obtained considerable momentum as a result of its ability to generate complex and top notch parts at a cost-efficient price. The diecasting process includes injecting molten steel right into a mold and mildew under high stress, causing parts that are durable, light, and extremely detailed. This write-up checks out the development of diecasting in Malaysia, its advantages, the industries it serves, and the prospects of this important manufacturing strategy.  One of the primary factors for the success of diecasting in Malaysia is its strong production facilities. The country's calculated place in Southeast Asia, coupled with its reputable industrial community, has made it an attractive destination for diecasting operations. Malaysia's production field has been progressing swiftly, with a concentrate on premium manufacturing and innovation. The availability of experienced labor, progressed machinery, and efficient supply chains has added to Malaysia's growing reputation for top quality diecast items. The automotive, electronics, and consumer goods industries in Malaysia have actually significantly depended on diecasting to produce lightweight, high-strength parts that meet worldwide requirements. As Malaysia's production base remains to broaden, diecasting will certainly play a vital function in sustaining the nation's economic development. The capability to produce detailed and in-depth components is just one of the main benefits of diecasting. The process enables suppliers to develop elements with intricate geometries, such as slim wall surfaces, damages, and detailed surface area functions, which would certainly be challenging to accomplish with various other traditional manufacturing approaches. This capacity has made diecasting an eye-catching choice for industries that need high precision and intricacy in their parts. The vehicle market, for example, relies upon diecasting to create lightweight and sturdy parts that aid improve fuel performance and total automobile performance. Furthermore, diecasting offers a high level of repeatability and uniformity, making sure that each part produced is virtually similar to the following, which is essential for sectors that require mass production of standard components. The diecasting industry in Malaysia is not nearly producing parts; it likewise entails taking on advanced innovations to improve manufacturing efficiency. As markets remain to demand better, much faster manufacturing times, and a lot more complex parts, diecasting manufacturers in Malaysia have actually embraced automation and progressed robotics. Automation allows for specific control over the diecasting procedure, minimizing human mistake and improving consistency in production. The use of robots for jobs like mold handling, metal injection, and part elimination further improves the performance of the process. Moreover, Malaysia's diecasting field has incorporated innovative materials such as light weight aluminum, zinc, and magnesium alloys, which are lighter and stronger than standard products. These developments guarantee that Malaysian manufacturers can generate high-performance parts that satisfy the advancing needs of global markets. To gather extra details please head to https://www.senadiecasting.com.my/

One of the primary factors for the success of diecasting in Malaysia is its strong production facilities. The country's calculated place in Southeast Asia, coupled with its reputable industrial community, has made it an attractive destination for diecasting operations. Malaysia's production field has been progressing swiftly, with a concentrate on premium manufacturing and innovation. The availability of experienced labor, progressed machinery, and efficient supply chains has added to Malaysia's growing reputation for top quality diecast items. The automotive, electronics, and consumer goods industries in Malaysia have actually significantly depended on diecasting to produce lightweight, high-strength parts that meet worldwide requirements. As Malaysia's production base remains to broaden, diecasting will certainly play a vital function in sustaining the nation's economic development. The capability to produce detailed and in-depth components is just one of the main benefits of diecasting. The process enables suppliers to develop elements with intricate geometries, such as slim wall surfaces, damages, and detailed surface area functions, which would certainly be challenging to accomplish with various other traditional manufacturing approaches. This capacity has made diecasting an eye-catching choice for industries that need high precision and intricacy in their parts. The vehicle market, for example, relies upon diecasting to create lightweight and sturdy parts that aid improve fuel performance and total automobile performance. Furthermore, diecasting offers a high level of repeatability and uniformity, making sure that each part produced is virtually similar to the following, which is essential for sectors that require mass production of standard components. The diecasting industry in Malaysia is not nearly producing parts; it likewise entails taking on advanced innovations to improve manufacturing efficiency. As markets remain to demand better, much faster manufacturing times, and a lot more complex parts, diecasting manufacturers in Malaysia have actually embraced automation and progressed robotics. Automation allows for specific control over the diecasting procedure, minimizing human mistake and improving consistency in production. The use of robots for jobs like mold handling, metal injection, and part elimination further improves the performance of the process. Moreover, Malaysia's diecasting field has incorporated innovative materials such as light weight aluminum, zinc, and magnesium alloys, which are lighter and stronger than standard products. These developments guarantee that Malaysian manufacturers can generate high-performance parts that satisfy the advancing needs of global markets. To gather extra details please head to https://www.senadiecasting.com.my/  The development of diecasting in Malaysia is likewise supported by a strong export market. As the country's diecasting abilities boost, more Malaysian manufacturers can satisfy the needs of worldwide clients. Malaysia exports diecast products to a selection of regions, consisting of The United States and Canada, Europe, and Asia, with a certain focus on the vehicle, electronics, and durable goods sectors. The nation's reputation for creating top notch, exact components has made it an eye-catching companion for international firms aiming to source dependable components. Malaysia's profession contracts with various nations and its subscription in regional companies such as Organization of Southeast Asian Nations have additional strengthened its position as an export center for diecast products. As global need for diecast components continues to grow, Malaysia is well-positioned to take advantage of this possibility and increase its share of the worldwide market. In spite of the numerous advantages of diecasting, the sector likewise encounters a number of difficulties. One of the key concerns is the ecological influence of the process. Making use of molten steels and the high power demands of diecasting can result in considerable energy consumption and emissions, which can add to the carbon footprint of manufacturers. As sustainability becomes a progressively crucial consideration in worldwide manufacturing, there is expanding pressure on diecasting companies in Malaysia to take on greener methods. This has caused the advancement of more energy-efficient equipments, as well as improvements in product recycling and waste decrease. By investing in these modern technologies and adopting more sustainable practices, the Malaysian diecasting sector can remain to grow while minimizing its environmental effect.

The development of diecasting in Malaysia is likewise supported by a strong export market. As the country's diecasting abilities boost, more Malaysian manufacturers can satisfy the needs of worldwide clients. Malaysia exports diecast products to a selection of regions, consisting of The United States and Canada, Europe, and Asia, with a certain focus on the vehicle, electronics, and durable goods sectors. The nation's reputation for creating top notch, exact components has made it an eye-catching companion for international firms aiming to source dependable components. Malaysia's profession contracts with various nations and its subscription in regional companies such as Organization of Southeast Asian Nations have additional strengthened its position as an export center for diecast products. As global need for diecast components continues to grow, Malaysia is well-positioned to take advantage of this possibility and increase its share of the worldwide market. In spite of the numerous advantages of diecasting, the sector likewise encounters a number of difficulties. One of the key concerns is the ecological influence of the process. Making use of molten steels and the high power demands of diecasting can result in considerable energy consumption and emissions, which can add to the carbon footprint of manufacturers. As sustainability becomes a progressively crucial consideration in worldwide manufacturing, there is expanding pressure on diecasting companies in Malaysia to take on greener methods. This has caused the advancement of more energy-efficient equipments, as well as improvements in product recycling and waste decrease. By investing in these modern technologies and adopting more sustainable practices, the Malaysian diecasting sector can remain to grow while minimizing its environmental effect.